OEM/ODM Services About Our Factory

We are a top Natural Soap manufacturer with our own large factory and substantial production capacity. With over ten years of experience in soap production and R&D, we have a team of experienced technical engineers and a trade team providing pre-sale and after-sale support. We can handle wholesale and OEM orders, offering one-stop service for a worry-free transaction. Contact us today to get free samples.

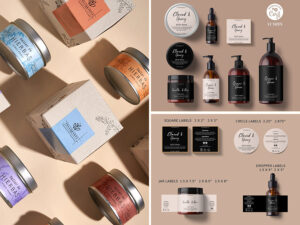

What We Offer

Why Choose Us As Your Partner

Rich manufacturing experience, intimate trade services

About Poleview Biotechnology Co., LTD

Preview Biotechnology is a leading OEM manufacturer specializing in the production of high-quality personal care and skin care products to meet customers' needs. We continually adopt the latest technologies and implement optimal production systems while providing comprehensive support from product development to manufacturing and quality control to maximize each customer's brand value.

In addition, we always adapt to changes in the personal care industry and are committed to continuous innovation to create new value for our customers.

We will continue improving quality, developing environmentally friendly products, and striving to grow with our customers. We sincerely thank you for your continued support and guidance.

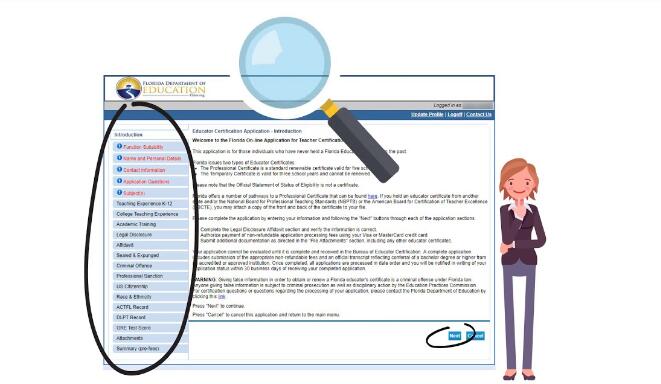

We Simplify OEM ODM Personal Care/Skincare for Our Client

1. Consultation

Begin with a consultation to craft a tailored business plan, focusing on your brand's position, sales channels, product selection, and marketing strategy.

2. Sample Order

Start your journey by testing our products and services with a sample order, ensuring we meet your project's requirements.

3. Trial Use Of the Sample and Feedback

Evaluate the sample to select the ideal formula for your brand, ensuring uniqueness and satisfaction.

4. Finalize Product and Packaging

Decide on the formula and packaging details, from bottle style to labeling. Upon mutual agreement, proceed with a deposit to commence production.

5. Packaging Design

Our designers will work with you to create multiple packaging design options, incorporating your ideas until complete satisfaction is achieved.

6. Finalization and Proofing

Post-design finalization, we conduct package proofing to preview your product before mass production.

7. Confirming Official Order

With everything confirmed, we place and oversee the order for raw materials and packaging, ensuring quality and timely execution.

8. Production and Delivery

We keep you informed throughout production and shipping, and we are committed to providing seamless, hassle-free service.