How to make soap with lye

What is Lye?

Lye is an inorganic compound, commonly referred to as sodium hydroxide or caustic soda. Typically found in dry bright white flakes, this compound is water soluble and often used to make Lye solution for the process of saponification, the fancy way to say, "making soap".

What Is Lye Made Of?

Lye is a highly alkaline chemical solution. The most common is sodium hydroxide, NaOH, but lye can also refer to potassium hydroxide, KOH.

As an alkali, lye solution is highly basic. If you remember your high school chemistry days, pH exists on a scale from 0 to 14. Acids are at the lower of the spectrum, while bases, also known as alkaline substances, are at the higher end.

- Lemon juice has a pH of 2

- Water has a pH of 7 (neutral)

- Lye has a pH of 13

Both strong acids and strong bases are caustic and can damage human skin, which is why lye is often misunderstood. If lye comes in contact with your skin, it begins to react with surface oils—a painful prospect that can lead to burns and irritation.

For this reason, many might choose to work with melt-and-pour soap, or soap that is pre-prepared with lye and ready to have extra ingredients added like essential oils and colorants.

What is lye used for?

This chemical is essential to a variety of industrial purposes, the most famous of which is making homemade soap. Others include:

- Surface disinfectant

- Curing food

- Manufacturing processes

- Adjusting the pH of formulations

Why is Lye needed in soap?

When creating soap, mixing fats and oils together, you need a method of fully combining the oils so that the mixture can saponify to be turned into a hard soap bar. Lye is the standard alkaline used to form the chemical reaction needed to take place. Without it, you simply won't make any soap! There are alternatives to Lye, given that sodium hydroxide was invented after the creation of the soap bar we know and love today. Original, all Natural Soap recipes, used a mixture of hardwood and water to create a strong alkali known as 'potash', strong enough to allow the chemical reaction to occur, combining the oils in the mixture.

How is lye added to soaps?

The process typically involves mixing lye with oils or butters, which contribute to the soap's scents and other natural properties, such as vitamins and minerals.

After we ground, render, and filter our suet (beef fat), we add lye to our completed tallow product. The reaction between oil and lye leaves no residue in the finished product. At the end of the soapmaking process, there's no lye left in your soap—it forms a bond with oil and becomes soap!

How to make soap with lye

Using lye (sodium hydroxide) for soap making is a critical step in the cold process method. Here’s a detailed guide on how to safely use lye in soap making:

Safety Precautions

- Protective Gear: Always wear gloves, goggles, and long sleeves to protect your skin and eyes from lye, which is caustic.

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes.

- Materials: Use heat-resistant glass or stainless steel containers for mixing lye and water. Avoid aluminum as lye reacts with it.

Ingredients

- Lye (Sodium Hydroxide): Measure based on your recipe.

- Water: Distilled water is recommended for safety and purity.

- Oils/Fats: Choose oils like olive oil, coconut oil, or palm oil, depending on your recipe.

- Optional Additives: Essential oils, colorants, or exfoliants.

Steps for Using Lye in Soap Making

-

Measure Ingredients:

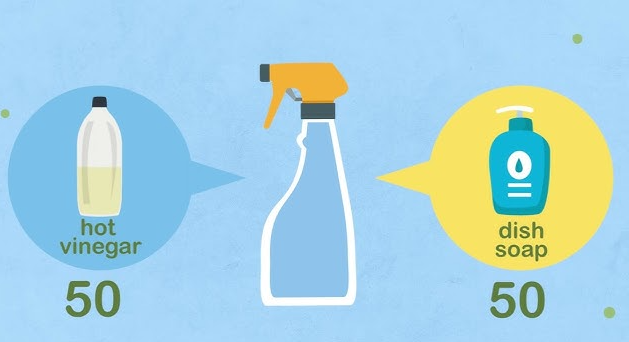

- Use a digital scale to accurately weigh your lye and water. A common ratio is 1 part lye to 2 parts water, but it depends on your specific recipe. -

Mix Lye and Water:

- In a well-ventilated area, slowly add the lye to the water (never the other way around, as it can cause a violent reaction). Stir gently with a stainless steel or heat-resistant plastic spoon until dissolved. The mixture will heat up and release fumes; allow it to cool in a safe place. -

Prepare Oils:

- While the lye solution cools, measure and melt your oils in a separate container. If you're using solid fats (like coconut oil), melt them completely before combining with liquid oils. -

Combine Lye and Oils:

- Once both the lye solution and oils are around the same temperature (ideally between 95°F and 105°F), slowly pour the lye solution into the oils while stirring gently. Use a stick blender to mix until you reach "trace" (when the mixture thickens and leaves a trail on the surface). -

Add Optional Ingredients:

- At trace, you can add any essential oils, colorants, or other additives. Mix thoroughly. -

Pour into Molds:

- Pour the soap mixture into molds. Tap gently to remove air bubbles. -

Insulate and Cure:

- Cover the molds with a towel to insulate them and allow the soap to saponify for 24 to 48 hours. After this period, unmold the soap and cut it into bars. -

Cure the Soap:

- Place the cut bars on a drying rack in a cool, dry place for 4 to 6 weeks to complete the curing process. This allows the soap to harden and the lye to neutralize.

Important Notes

- Lye Calculator: Use a lye calculator to determine the exact amount of lye needed based on the oils you are using.

- Storage: Store lye in a cool, dry place, away from children and pets.

- Testing: Always test your soap with pH strips to ensure it is safe for skin use before using or gifting.