How to make soap at home step by step

What is soap?

‘Soap’ is defined as fat or oil combined with an alkali. The oil is derived from an animal or plant, whereas the alkali is a chemical known as lye. The lye used in the production of bar soap is sodium hydroxide. Potassium hydroxide is required for liquid soap.

Soap is produced by combining and then heating oil and lye. This chemical reaction is known as saponification. With soap bar production, the formula is then pressed into moulds.

When was soap invented?

Records show ancient Egyptians bathed regularly. The Ebers papyrus, a medical document from about 1500 BC describes combining animal and vegetable oils with alkaline salts to form a soap-like material used for treating skin diseases, as well as for washing.

Many other ancient civilizations also used early forms of soap. Soap got its name from an ancient Roman legend about Mount Sapo. Rain would wash down the mountain mixing with animal fat and ashes, resulting in a clay mixture found to make cleaning easier.

How does soap work?

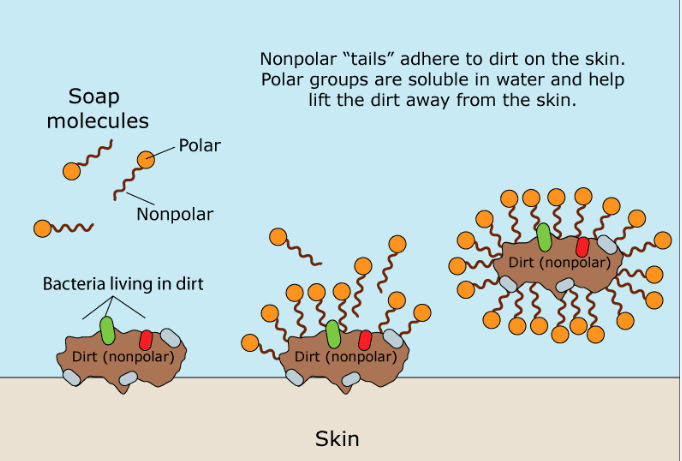

Soap is made from the combination of a fat and an alkaline material, which react through a chemical process called saponification.

Saponification makes a substance that can combine with both water and oil, explains Anastasia Bendebury, PhD, who is a microbiologist. When dissolved in water, soap forms an amphoteric micelle, or a group of molecules that are attracted to water on the outside and oil on the inside.

But when soap encounters oils, they get mixed into the center of the amphoteric micelle. So, when you wash your hands with soap and water, the combination is able to carry away grease, grime, and dirt — along with the germs they contain.

The benefits of using soap

Soaps are good for your skin

Effectively cleanses the skin: very powerful cleansing agents, a unique feeling of cleanness.

Helps to maintain the skin's hydrolipidic film: to a certain extent, the action of the soap stimulates the glands that produce sebum, which is one of the elements that makes up the skin's protective barrier.

Soap has a bacteriostatic and fungistatic effects: it inhibits the growth of bacteria and fungi.

Soaps are good for the environment

Most soaps contain good levels of naturalness and biodegradability.

Duration of use: a bar of soap can be used for a longer time when compared with a liquid cleansing product. On average, in terms of quantity, we use more liquid cleansing product than solid soap. If we start with exactly the same amount of both products, the bar of soap will last longer than the liquid soap.

How to make soap at home

Ingredients and equipment

- coconut oil ⅔ cup (helps to produce lather)

- olive oil ⅔ cup

- other liquid oil ⅔ cup – like almond oil, grapeseed, sunflower or safflower oil

- ¼ cup lye – also called 100% sodium hydroxide

- ¾ cup cool water (use distilled or purified)

- Quart canning jar

- Pint canning jar

- Soap molds

- Gloves and protective goggles

Instructions

Step 1: Cover your work area. Put your gloves and other protective wear on. Measure your water into the quart canning jar. Have a spoon ready. Measure your lye, making sure you have exactly ¼ cup. Slowly pour the lye into the water (never the water into lye) stirring as you go. Stand back while you stir to avoid the fumes. When the water starts to clear, you can allow it to sit while you move to the next step. It will generate heat as the chemical reaction occurs.

Step 2: In the pint jar, add your three oils together. They should just make a pint. Heat in a microwave for about a minute, or place the jar of oils in a pan of water to heat. Check the temperature of your oils – it should be about 120°F or so. Although you can use a soap-maker thermometer, a regular meat thermometer will also work. Your lye should have come down by then to about 120°F. Wait for both to cool somewhere between 95°F and 105°F. This is critical for soap making. Too low and it'll come together quickly, but be coarse and crumbly.

Step 3: When both the lye and oils are at the right temperature, pour the oils into a mixing bowl. Slowly add the lye, stirring until it's all mixed. Stir by hand for a full 5 minutes with any spoon or spatula that is heat-resistant. It's very important to get as much of the lye in contact with as much of the soap as possible. After about 5 minutes, you can keep stirring or you can use an immersion blender. The soap mixture will lighten in color and become thick. When it looks like vanilla pudding it's ready.

Step 4: Add your herbs, essential oils or other additions. Stir thoroughly to combine. Pour the mixture into mold(s) and cover with plastic wrap. Set in an old towel and wrap it up. This will keep the residual heat in and start the saponification process.

Step 5: After 24 hours, check your soap. If it's still warm or soft, allow it to sit another 12 to 24 hours. When it's cold and firm, turn it out onto a piece of parchment paper or baking rack. If using a loaf pan as your mold, cut into bars at this point. Allow soap to cure for 4 weeks or so. Be sure to turn it over once a week to expose all the sides to air, or put it on a backing rack to allow air to circulate.

Step 6: When your soap is fully cured, wrap it in wax paper or keep it in an airtight container. Hand-made soap creates its own glycerin, which is a humectant, pulling moisture from the air. It should be wrapped to keep it from attracting dust and debris with the moisture. Clean your equipment that has been exposed to lye. You can neutralize the lye with white vinegar, then wash the equipment well as you normally would.

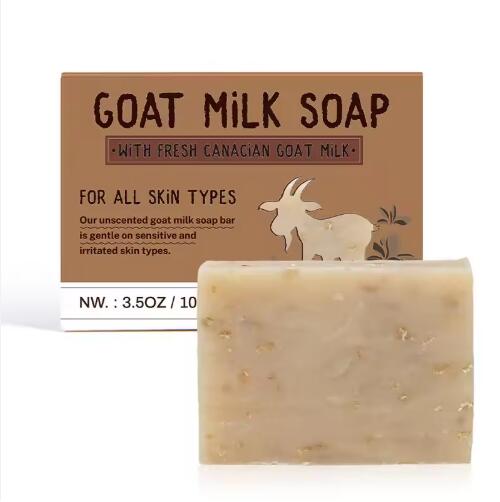

Wholesale soap base for your store

Handcrafted soap can be made from scratch, by either hot or cold process, or created from a ready-made Soap Base. The method(s) chosen by a soapmaker are based on personal preference and the desired end result. In some cases, a final soap may contain both soap from scratch and ready-made soap base.

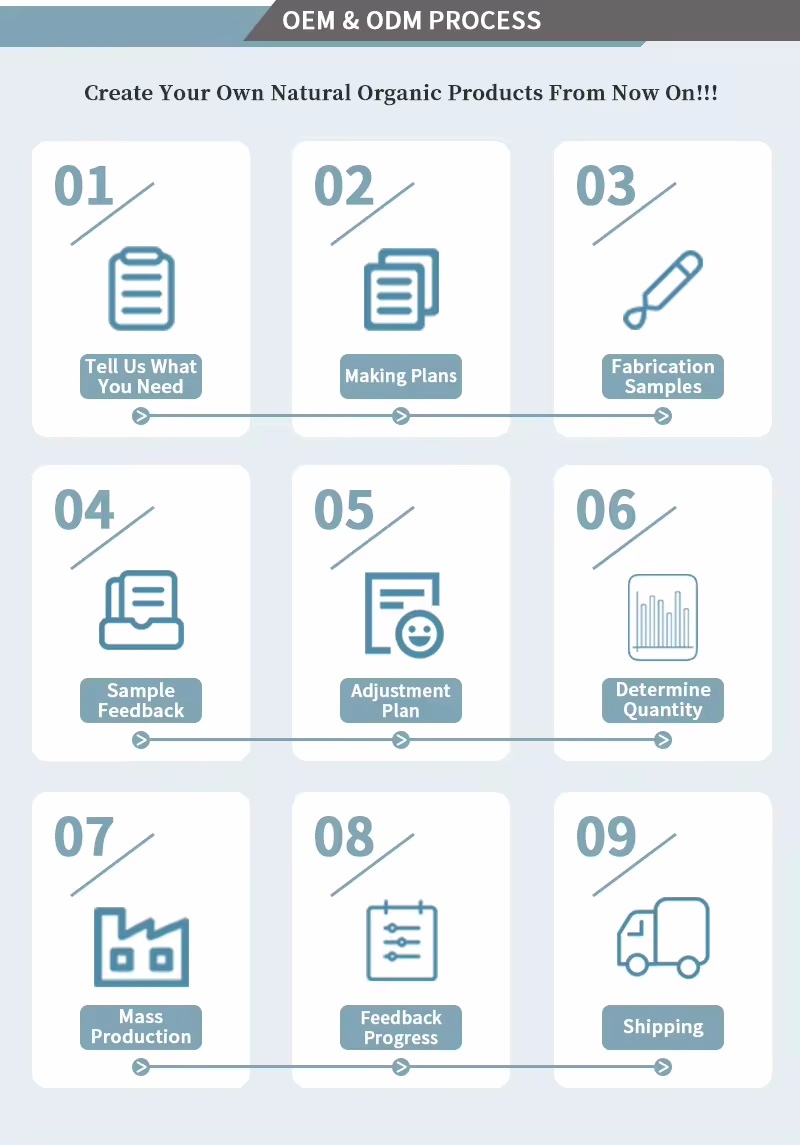

If you want to simplify the soap making process, we recommend using the soap base directly. Only need to cut the soap base and melt it at high temperature, add various fragrances or other substances, and then pour it into the grinder waiting for re-solidification to make their own soap.As a professional soap manufacturer in China, Poleview Biotechnology Co., Ltd. provides soap base wholesale and OEM. If you plan to sell soap base in your own store, please contact us for customization. We can provide free design and sample service, providing one-stop service.